Managing the physical inventory count

Once you have generated a list for the physical inventory count, you need to manage the count itself. Follow the general best practices for inventory counts. For example:

-

Schedule the count to take place while the store is closed.

-

Hire a third party vendor to perform the count for you, if necessary.

-

Create a zone map of the store that identifies which sections of the store need to be counted.

There are also some practical things you can do to make the physical inventory count run smoothly:

-

Use hand-held devices like scanners to count items. With these devices, your team members can scan or input ILC codes on labels and then enter the physical item count. This information can then be exported to a tab delimited or comma delimited file that can be easily imported into Store Manager.

-

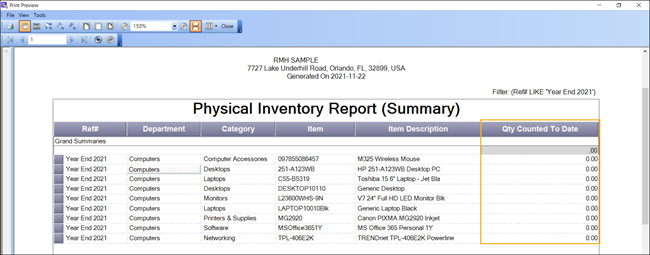

If you must use paper and pencil to count items, print copies of the Physical Inventory Report to aid with the count. You can use the Reference No. of the physical inventory list to generate the report. Edit the report layout so it only includes relevant information like bin location, department, category, item lookup code, or item description. Do not include expected quantity.

-

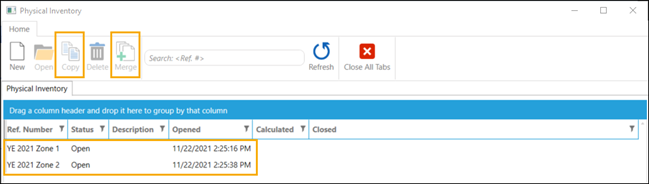

Create copies of the physical inventory list for specific team members or store zones and merge the results. This is helpful if you have the same item displayed in different sections of the store. For example, you might have a large display of Coca Cola products at the entrance to the store, but the same products may also be displayed in coolers, in aisles, or in the POS lanes. In Store Manager you can create copies of the physical inventory list and then merge the results for the final calculation. Each copy of the physical inventory list will have a unique number. Assign each number to a different team member for the inventory count.